What is Arc Flash?

An arc flash is the release of energy that occurs during an electrical fault when current flows through the air between two live conductors, resulting in the form of light, heat, sound, and a blast of arc products that may consist of vaporized components of enclosure material (copper, steel, or aluminum). According to the National Fire Protection Association (NFPA) and the Institute of Electrical and Electronics Engineers (IEEE), every year roughly 30,000 arc flash incidents happen, causing 7,000 burn injuries, and 2,000 workers being admitted to burn centers for extended injury treatment caused by arc flash.

This NFPA video shows what happens during an electrical arc flash:

If necessary, a copy of the video transcript (PDF) is available.

NFPA standard 70E requires electrical equipment owners to perform arc flash hazard analysis to determine the arc flash boundary, the incident energy at the working distance, and the personal protective equipment (PPE) that workers within the arc flash boundary must use. PPE is not intended to prevent all injuries, but is intended to mitigate the impact of an arc flash, should one occur.

Need Service?

Facilities Service Center

Main: 512-471-2020

UT Works

General Inquiries: facilities@austin.utexas.edu

Events & Moving:

fs-events@austin.utexas.edu

How do we avoid Arc Flash at UT Austin?

The university takes multiple precautions to avoid arc flash:

- Only facilities personnel, trained on establishing a Electrical Safe Work Condition (ESWC), shall de-energize the equipment affected and perform proper lockout/tagout procedures.

- Energized work is prohibited on exposed electrical parts with nominal voltage of more than 50 volts, unless qualified workers who are conducting testing or trouble-shooting and de-energizing is not feasible, or de-energizing the part(s) will create a greater hazard.

- Only qualified persons shall be permitted to work on electrical conductors or circuit parts that have not been put into an electrically safe work condition.

- Personnel working on or near exposed energized electrical parts shall use appropriate personal protective equipment (PPE) and tools to protect themselves from potential electrical shock, arc flash, and fire hazards.

What is Arc Flash Analysis?

Arc flash analysis is a technical study to evaluate electrical equipment and power systems, in order to predict a worker’s potential exposure to arc flash energy. The study is prepared by a trained safety expert and conducted for the purposes of injury prevention and determination of safe work practices, arc flash boundary, and appropriate levels of personal protective equipment (PPE).

The arc flash analysis must be updated when a major modification or renovation takes place. It must be reviewed periodically, not to exceed five years, to account for changes in the electrical distribution system that may affect the results of the arc flash incident energy hazard.

The arc flash hazard analysis and recommended PPE levels are no substitutes for safe work practices. Certain burn injuries can occur even when adequate PPE is utilized. Recommended PPE may provide little or no protection against arc blast and its effects when circuits or equipment have not been placed in an electrically safe work condition .

Why is the program required?

The Facilities Operations and Maintenance division of Facilities Services has been charged with developing an Arc Flash Analysis Program (AFAP) on behalf of the university. The program was established to develop the standard procedures for implementing and continued compliance with the national and industry standards governing electrical safety.

The guidelines for work involving electrical hazards and the selection of arc flash protective equipment are mandated by current National Fire Protection Association (NFPA) standard 70E. This standard requires electrical equipment owners to perform arc flash hazard analysis to determine the arc flash boundary, the incident energy at the working distance, and the personal protective equipment (PPE) that employees must use within the arc flash boundary. In selecting the proper PPE two methods are used, the incident energy analysis and the arc flash PPE category method. The University adapted the incident energy analysis is the more stringent method.

Institute of Electrical and Electronics Engineers (IEEE) standard 1584 provides the standard for calculating arc flash energy levels at different points in the electrical power system.

Progress at UT Main Campus

Progress on Arc Flash Analysis on the university's Main Campus is detailed in a semi-annual report, prepared by the AFAP team.

Warning Labels

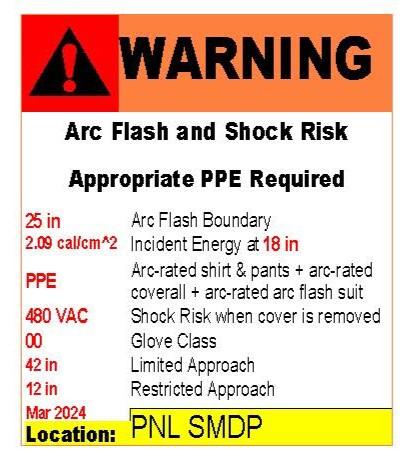

National Fire Protection Association (NFPA) standard 70E states that labels must be posted on electrical equipment to "warn employees about electrical hazards that might endanger them." In compliance with the standard, the university requires the following information for arc flash labels posted on identified equipment:

- Limited approach distance

- Restricted approach distance

- Equipment designation/location

- Voltage/shock risk when cover is removed

- Arc flash protection boundary

- Incident energy at working distance

- Working distance

- Personal protective equipment required

- Date arc flash analysis is prepared

- Glove class

Here is an example:

Roles and Responsibilities

FOM - Arc Flash Analysis Team:

- Implement arc flash studies that are missing or incomplete on existing buildings at the university's Main Campus and J. J. Pickle Research Campus.

- Maintain copies of documents and electronic files used for the electrical studies. This includes copies of all short-circuit coordination studies, arc flash studies, and single-line diagrams, as well as documentation on subsequent electrical system changes.

- Implement a five-year electrical single-line (power-flow study) review and update as part of the arc flash analysis.

Shop Supervisors / Trade Leaders:

- Ensure respective employees comply with all provisions of the Arc Flash Analysis Program.

- Ensure respective employees are trained in arc flash hazards and observance of electrical safety procedures.

- Assist arc flash analysis team in a five-year review and update of existing arc flash analysis.

- Report to the Primary AFAP Engineer any discrepancies between field electrical system distribution and the single-line diagram created with SKM Systems Analysis, Inc. (SKM) electrical engineering software.

Project Managers:

- Coordinate with the Primary AFAP Engineer in maintaining up-to-date single-line diagrams, panel schedules, and SKM models.

- Include a review of the arc flash study in any major modification or renovation to the electrical system of a building.

- Deliver reviewed and completed SKM files and other electrical power system documentation to the Primary AFAP Engineer as part of the project sign-off.

AFA in Project Management - Flow Chart

View a flow chart (PDF) that illustrates the process for determining when project managers should incorporate arc flash analysis into the scope of projects at the university. Additional information, including the full standard operating procedures (SOP), can be found here (PDF).

Program Contacts

For questions or additional information about the university's Arc Flash Analysis Program, contact:

Leonard Uy

Arc Flash Engineer, Engineering & Technical Support, FOM, Facilities Services

leonard.uy@austin.utexas.edu

512-475-8407

Sean Mackenzie

Assistant Director, Engineering & Technical Support, FOM, Facilities Services

sean.mackenzie@austin.utexas.edu

Julia Ogden

Master Electrician, Engineering & Technical Support, FOM, Facilities Services

julia.ogden@austin.utexas.edu

512-232-9479